Check Valves

The check valve is a valve that constantly maintains fluid flow in a constant direction and prevents reverse flow. The disc is pushed open by the fluid pressure, but when it flows backward, the disc is brought into close contact with the seat of the body by the back pressure to prevent backflow. There are three typical types of check valves (swing check valve, lift check valve, and wafer check valve).

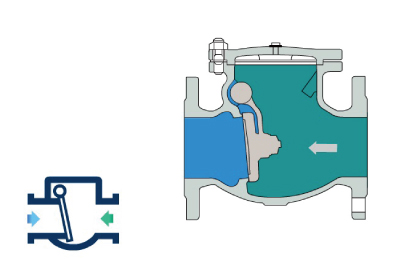

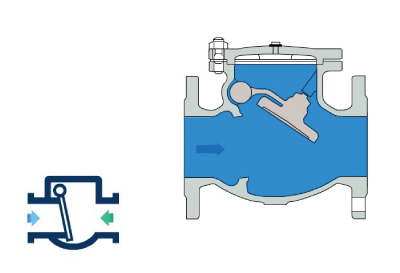

Swing check valve

This section introduces the operation principle for flowing and stopping the fluid of three types of check valves.

One end of a disc-shaped disc is made into a “wing-type” structure, which is free to move by hanging on a body, etc., and has a structure in which pressure loss is small and fluid flows easily. It can be used not only for horizontal piping, but also for vertical piping (flowing from bottom to top).

The product information of the swing check is included in the valve catalog for each material. Select the valve material and refer to the catalog.

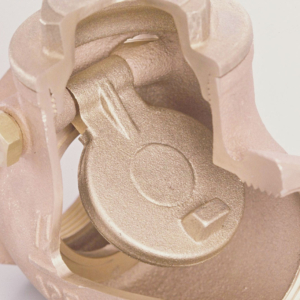

Cast Steel Swing Check Valves (with internal hinge pin)

- No risk of leakage from a hinge pin plug

- Anti rotation disc design

- Same face to face dimensions and flow characteristics as the current design

- Meets the latest editions API 594: 2017

Lift check valve

The stem, handle, and other open/close operation parts are removed from the globe valve, and the cover is attached. Major products are those with large fluid resistance and small bore size.

The product information of the swing check is included in the valve catalog for each material. Select the valve material and refer to the catalog.

Wafer check valve

The body is wafer-shaped, making it much thinner and lighter than conventional shock-absorbing check valves. This is a multi-functional, high-performance shock-absorbing check valve with a built-in bypass circuit and excellent sealing performance, despite being a thin-type boiler.

The product information of the swing check is included in the valve catalog for each material. Select the valve material and refer to the catalog.